For modern pig farmers, maintaining efficiency, improving animal welfare, and ensuring optimal productivity all depend heavily on the use of advanced machines and equipment. In recent decades, the integration of technology into pig farming has transformed the industry—boosting biosecurity, reducing labor intensity, and enabling precision farming. Whether you run a small family operation or manage a large-scale commercial facility, the right set of machines can significantly enhance farm management and economic outcomes.

In this article, we’ll explore some of the essential machines and equipment commonly used in pig farms today, examine their roles in daily operations, and consider how global pig farmers—especially in the U.S., Europe, and Asia—integrate these tools into their farming systems. The focus will be on practicality, real-world benefits, and how this equipment supports animal health, growth monitoring, and overall productivity.

Feeding Systems: Precision and Efficiency

Automatic Dry Feeders and Wet-Dry Feeders

One of the most basic yet vital machines on a pig farm is the feeding system. In traditional systems, pigs were fed manually, which is both time-consuming and prone to inconsistency. Today, most farms use automatic dry or wet-dry feeders. These systems dispense feed in regulated portions, reducing waste and ensuring consistent nutrition across all pigs.

In countries like Denmark and the Netherlands, automatic feeding systems are widely used due to their labor-saving benefits and ability to track feed consumption. Farmers can program different rations for piglets, growers, and finishers, optimizing growth performance while controlling costs.

Liquid Feeding Systems

For larger farms, liquid feeding systems—which mix feed with water and sometimes fermented by-products—offer improved digestibility and faster weight gain. In Germany and France, where sustainability is a priority, farms often incorporate food industry by-products (like whey or brewer’s grains) into liquid feeds, reducing waste while maintaining animal performance.

Climate Control Equipment: Keeping Pigs Comfortable

Ventilation Fans and Climate Controllers

Pigs are extremely sensitive to temperature fluctuations, especially in confinement systems. To maintain optimal conditions, farms use large ventilation fans combined with smart climate controllers. These systems monitor air quality, temperature, and humidity in real-time and automatically adjust fans, heaters, or coolers as needed.

American and Canadian farms often rely on negative pressure ventilation systems to ensure a steady flow of fresh air, while Chinese and Thai farms increasingly use automatic curtain systems to adjust airflow based on ambient conditions.

Heating Systems: Infrared Lamps and Underfloor Heating

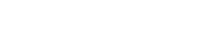

For piglets, thermal comfort is critical in the first few weeks of life. Infrared heat lamps and underfloor heating panels provide localized warmth, preventing chilling and reducing mortality. These heating systems are especially common in farrowing pens in Europe and North America, where animal welfare standards are tightly regulated.

Waste Management: Hygiene and Environmental Control

Slatted Flooring and Manure Removal Systems

Slatted floors are a key feature of modern pig housing. They allow manure to fall through gaps into a pit or channel below, reducing contact between pigs and waste. Beneath the slats, mechanical scrapers or vacuum systems collect and transport manure to storage lagoons or anaerobic digesters.

In the U.S., automated scraper systems are common in finishing barns, while Scandinavian farms often use vacuum systems that transport manure with minimal odor or ammonia release—an important consideration in eco-sensitive regions.

Anaerobic Digesters

In countries focused on green energy, like Germany and the Netherlands, anaerobic digesters convert pig manure into biogas. These systems reduce greenhouse gas emissions and generate electricity or heat for farm use. Though expensive to install, they are increasingly subsidized and seen as a solution to the environmental impact of intensive pig farming.

Health and Monitoring Equipment

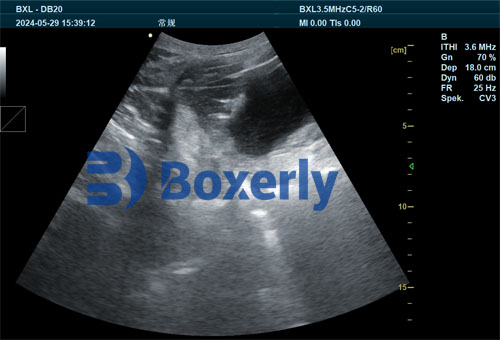

Ultrasound for Reproductive and Growth Assessment

Ultrasound machines are widely used to confirm pregnancy and monitor fetal development in sows. Portable veterinary ultrasound equipment—such as the B-mode scanners—is now essential on most modern farms. These machines are non-invasive, provide immediate results, and help reduce the number of non-productive days (NPD) in breeding sows.

In North America and Europe, farmers frequently use ultrasound to evaluate sow backfat thickness—a key metric for adjusting feed rations and preventing issues like poor conception or farrowing complications. In Asia, portable ultrasound scanners have also become increasingly popular due to their cost-effectiveness and real-time imaging.

Farrowing and Breeding Equipment

Farrowing Crates and Pens

Farrowing crates are designed to protect piglets from being crushed by the sow while allowing her enough space to feed and rest. These crates often include creep areas with heating pads and piglet feeders. While controversial in some regions due to animal welfare concerns, they remain widely used across the U.S. and parts of Asia for their proven role in improving piglet survival.

Artificial Insemination (AI) Equipment

Breeding programs on commercial farms increasingly rely on artificial insemination to improve genetic traits and reproductive efficiency. Equipment such as semen storage tanks, catheters, and insemination boars are standard in AI setups. In Spain and Brazil, for instance, AI adoption rates exceed 90% in large pig operations.

Weighing and Sorting Systems

Automatic Pig Weighers

Weight tracking is critical for managing growth rates and marketing decisions. Modern pig farms often install automatic weigh scales at feeding stations or exit gates. These systems capture weight data without human intervention, providing a clear picture of growth trends.

Some advanced systems, particularly in the U.K. and Germany, also sort pigs based on weight, directing them to different pens or feeding zones to ensure uniform growth before marketing. This minimizes variability and improves slaughterhouse efficiency.

Cleaning and Disinfection Machines

High-Pressure Washers and Foamers

Effective sanitation reduces the risk of disease outbreaks. High-pressure washers combined with foaming disinfectants are used between production cycles to clean pens, walls, and equipment. Mobile units are common, and in some automated systems, ceiling-mounted sprayers deliver disinfectants throughout the building.

In high-biosecurity operations, such as those in Japan and Korea, robot-assisted cleaning units are emerging. These robots follow pre-programmed routes, spraying and washing pens with minimal labor input.

Data and Farm Management Software

Integrated Farm Management Systems

Modern pig farming has embraced digitalization. Computerized systems now record feed intake, water consumption, temperature, weight gain, reproduction data, and medication records. Platforms like PigCHAMP (U.S.), AgriFarm (Europe), and SmartPig (China) help farmers analyze herd performance, identify problems early, and make data-driven decisions.

These systems are accessible via tablets and smartphones, allowing remote monitoring—a particularly valuable feature for large operations with multiple sites.

Conclusion

Pig farming has evolved from a labor-intensive, manual process to a highly mechanized and technology-driven industry. The machines and equipment now available—from precision feeders and climate control systems to ultrasound scanners and AI tools—not only improve productivity but also enhance animal health, welfare, and environmental sustainability.

By adopting these technologies, pig farmers across the globe are able to raise healthier pigs, reduce costs, and meet the growing global demand for pork more responsibly. As we look ahead, the future of pig farming will increasingly rely on smart, integrated systems that combine hardware, software, and data analytics to create truly precision-driven operations.

References

USDA Animal and Plant Health Inspection Service. (2022). Overview of Swine Industry Practices in the United States. https://www.aphis.usda.gov

Whitaker, D. A., & Smith, E. (2021). Veterinary Ultrasonography in Food-Producing Animals. Journal of Veterinary Imaging.

Pig Progress. (2023). Modern Tools and Equipment on Pig Farms. https://www.pigprogress.net

FAO. (2021). Good Practices for Pig Farming. https://www.fao.org/pig-farming

SmartPig Farm Technologies. (2024). Smart Monitoring and Control Systems in Pig Production. https://www.smartpigtech.com